Okwesibini, ubume kunye nomgaqo wokusebenza wekristale yolwelo. Ikristale elulwelo yahlukile kwimeko yesiqhelo eqinileyo, engamanzi kunye nerhasi yelizwe, ikuluhlu oluthile lobushushu zombini ulwelo kunye nekristale iimpawu ezimbini zobume bemeko, kunye nolungiselelo oluqhelekileyo lwemolekyuli yeekhompawundi zezinto eziphilayo, ikristale elulwelo esetyenziswa ngokuqhelekileyo kwisigaba sekristale yolwelo, ubume bemolekyuli yintonga eyondeziweyo, eyohlukileyo, phantsi kobude bekristale yangoku, malunga nobude bekristale. iimolekyuli ziya kwenza ujikelezo rhoqo 90o ilungiselelo, okubangela umahluko kwi transmittance, ukuze unikezelo lwamandla luvulwe kwaye luvaliwe xa umahluko phakathi ukukhanya nobumnyama. Ikristale yolwelo kwi-ADF yindlela yokuqhuba esebenzisa ngokuthe ngqo i-voltage yokuqhuba kwinqanaba le-pixel, ukwenzela ukuba i-crystal display ye-liquid ihambelane ngokuthe ngqo nomqondiso wombane osetyenzisiweyo. Ingcamango esisiseko ye-voltage esetyenzisiweyo kukusebenzisa ngokuqhubekayo intsimi yombane kwaye akukho ntsimi yombane esetyenzisiweyo phakathi kwesibini esihambelanayo se-electrode, kwaye umahluko kwi-transmittance uboniswa ngokobukhulu bendawo yombane esetyenzisiweyo.

Okwesithathu, ukubaluleka kwenani le-shading kunye neesekethe ezihambelanayo.Inombolo yomthunzi ibhekisela kwindlela i-ADF enokucoca ngayo ukukhanya, inkulu inombolo yomthunzi, encinci ukuhanjiswaADF, ngokweemfuno ze-welding ezahlukeneyo, khetha inombolo efanelekileyo ye-shading, inokuvumela i-welder ukuba igcine ukubonakala kakuhle ngexesha lomsebenzi, inokubona ngokucacileyo indawo ye-welding kwaye iqinisekise ukuthuthuzelwa okungcono, kukulungele ukuphucula umgangatho we-welding. Inombolo ye-shading iyisalathisi esibalulekileyo sobugcisa kwi-ADF, ngokuhambelana nembalelwano phakathi kwe-transmittance ratio ye-ADF kunye nenombolo ye-shading kumgangatho wesizwe wokukhusela amehlo e-welding, ukukhanya okubonakalayo, i-ultraviolet kunye ne-infrared transmission ratio yenombolo nganye ye-shading kufuneka ihlangabezane neemfuno zomgangatho.

Okokuqala, isihluzo se-welding sisebenzisa ikristale engamanziukukhanyaivalve ibizwa ngokuba LCD Welding Filter, ekubhekiselwa kuyo njenge-ADF; Inkqubo yokusebenza kwayo yile: umqondiso we-arc xa ukuthengiswa kwe-arc iguqulwa ibe ngumqondiso we-micro-ampere yangoku yityhubhu ye-photosensitive absorber, iguqulelwe kwi-resistor yesampulu ibe ngumqondiso we-voltage, idityaniswe yi-capacitance, isusa icandelo le-DC kwi-arc, kwaye emva koko ikhulise umqondiso we-voltage ngokusebenzisa isiphaluka sokwandisa umsebenzi, kunye nesekethi edibeneyo yokulawula i-Tpass ikhethiwe kunye nolawulo lwesekethe kwinethiwekhi ye-T. ukukhupha umyalelo wokuqhuba kwisekethe yomqhubi weLCD. Isekethe ye-LCD ye-drive drive itshintsha i-valve yokukhanya ukusuka kwimeko eqaqambileyo ukuya kwindawo emnyama, ukwenzela ukuba ugweme umonakalo wokukhanya kwe-arc kwiso le-welder. Umbane ofikelela kuma-48V wenza ikristale yolwelo imnyama ngoko nangoko, ize emva koko ivale amandla ombane aphezulu ngexesha elifutshane kakhulu, ukuze kuthintelwe ukuba amandla ombane aphezulu aqhubeke efakwa kwikristale elulwelo, konakalise ulwelo lwekristale chip, kunye nokwanda kokusetyenziswa kwamandla. I-voltage ye-DC kwisekethe ye-crystal drive ye-liquid, imveliso yayo ihambelana nomjikelo womsebenzi, iqhuba ivalve yokukhanya yekristale ukuba isebenze.

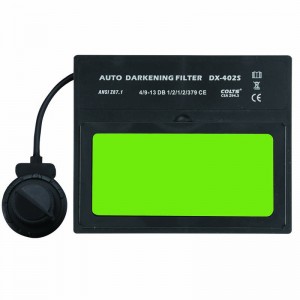

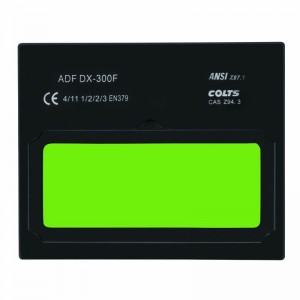

Okwesine, ukudityaniswa kwendibaniselwano yekristale elulwelo. Ifestile ye-ADF yenziwe ngeglasi egqunyiweyo, ivalve ephindwe kabini yolwelo oluyikristale kunye neqhekeza leglasi ekhuselayo (jonga umfanekiso 2), zonke ziyinxalenye yeglasi, kulula ukuqhawuka, ukuba iqhina phakathi kwabo aliqinanga, xa i-welding solute igalela kudityaniswe yikristale yolwelo, inokubangela ukuba indibaniselwano yekristale yolwelo iqhekeke, ke ngoko iyakwenzakalisa ulwelo lwekristale. luphawu olubalulekileyo lokhuseleko lwe-ADF. Emva kweemvavanyo ezininzi, ukusetyenziswa kweglu yangaphandle A, B yamacandelo amabini, ngokwendlela ye-3: 2 yomlinganiselo kwindawo ye-vacuum emva kokuvuselela, kwindawo yokucoca inqanaba le-100 usebenzisa umatshini wokuncamathisela ozenzekelayo wokukhupha kunye nokudibanisa, ukuqinisekisa ukuba iimpawu ze-ADF zolwelo lwekristale indibaniselwano kwi-en379-2003 kunye neemfuno ezihambelanayo zenkqubo yolwelo, ukusombulula i-crystal ehambelana neemfuno zayo.

Ixesha lokuposa: May-16-2022